Frequently Asked Questions About ThermoFIn and Radiant Heating

What is hydronic radiant heating?

A hydronic heating system uses heated water or a solution of water and propylene glycol circulated by a pump to heat a structure. Radiant Design & Supply, Inc.specializes in hydronic distribution systems. Hydronics allow for choices of energy sources for heating and cooling, versatility in the selection of distribution equipment, low energy consumption, low heat loss related to space heating distribution, and zoning to address diversity in building designs and uses. With hydronics we have the ability to address diverse heating applications such as domestic water or snow and ice melting with the same heating equipment. Even small residential systems that may predominantly use forced air for heating distribution and air conditioning can benefit from a hydronic heat source such as a high efficiency boiler that also provides domestic water heating. With radiant heating, air ducts and fans do not blow dust and allergens within your home, as forced air furnaces do.

Where can I buy ThermoFin and radiant heating equipment?

Contact RADIANT directly from our contact page on this site. We sell the components of a hydronic radiant heating system including ViegaPEX™ Barrier tubing or ComfortPro PEX A with Barrier tubing, boilers, and design of the system and tubing layout.

How do I order ThermoFin?

The ThermoFin plates are shipped 20 in a box. The plates are either 4' or 8' in length with channels for 3/8" or 1/2" nominal tubing size (1/2" OD or 5/8" OD). The plates can be cut with a carbide tipped blade for cutting non-ferrous metal.

We can give you a quote that includes shipping when we know the type of plate, length, tubing size, and quantity of boxes you are ordering. We also need your delivery address, and if it is commercial or residential. Smaller orders can generally be shipped via UPS Ground. If ordering more than 8 boxes, depending on the destination, the order may be shipped on a pallet. If the order will be sent on a pallet, we must know if you have a forklift or loading dock at the delivery address. The freight carriers charge a fee for the lift gate to unload a pallet where there is no forklift at the delivery site. If you are near the freight carrier's terminal, you can also request to pick up a pallet order at the freight terminal.

Contact us through the contact page of our website and we will provide prices as well as free small samples, if you want them. If you are a contractor, be sure to let us know.

How do I calculate how many plates to buy?

Square feet converted to linear feet of plates - if installed 8" on center, multiply by 1.5. If 6" on center, multiply by 2. If there are closets, counters, cupboards, refrigerator, etc., under which radiant heat plates do not have to be installed, in general, we subtract 10% from the square footage.

Is the radiant heating system separate from the other plumbing for the house?

It is a closed system that is not connected with the potable water plumbing or the drain waste and vent piping in a house.

Are radiant heating systems with ThermoFin energy efficient?

ThermoFin extruded aluminum heat transfer plates increase the efficiency of radiant heating systems. The thermal mass of the plate and the firm grip of the tubing that transfers heat from the hydronic fluid into the plate, make ThermoFin more energy efficient than tubing alone or other metal plate or board systems. Radiant heating with ThermoFin allows operation with low fluid temperatures that boost efficiency in a variety of ways. It decreases undirected heat losses from boilers, piping circuits, and other system components. Lower fluid temperatures allow boilers to pull more heat from exhaust gases, and less heat is lost up the flue. Low operating temperatures are needed to get the best operation of modern, high efficiency condensing boilers, heat pumps, and solar energy systems. Systems that can operate at lower temperatures can take advantage of new, sophisticated heating controls that increase comfort and efficiency by carefully regulating system temperatures. See the infrared product comparison on our website at The Heat Exchanger Blog.

Do you provide BTU output data comparing your product to others?

The output of a radiant floor is dependent on the average surface temperature of the floor but not necessarily exactly how it is brought to that temperature. Where increased efficiency shows up - one technique vs. another - is in the water temperature at which a given technique creates or affects the average surface temperature. Less efficient systems must operate at higher water temperatures.

Can radiant heating with ThermoFin aluminum plates be used with hardwood floors?

Yes. Hardwoods like oak are about half to a third as conductive as masonry materials like concrete or even dense materials like granite. Softwoods are just a little less conductive than hardwoods. Aluminum is roughly 237 times more conductive than concrete.

The thermal diffusivity of a material is also an issue. This relates the mass of the material with its conductivity. In radiant floors, the mass of the material determines how fast the system can change in temperature. Wood diffuses heat at a rate that is about 3.25 times that of concrete. Aluminum diffuses heat at a rate that is 45 times faster than concrete.

Our heavy gauge extruded aluminum heat transfer plate, ThermoFin, pulls heat out of the tubing and increases the area for heat transfer in a two-sided flat plate. This plate can be used in a variety of ways to conduct heat into and diffuse it through wood floors at a very high rate, even compared with concrete systems. In our over-the-floor ThermoFin U system, we prefer to bury the heat transfer plate below plywood sleepers to diffuse heat through the sleepers. This evens the temperature at the surface and carries the surface flooring at consistent, low temperatures that are just above the desired room air temperature.

Hardwood finish floors work great with ThermoFin radiant heating!

Does radiant floor heating damage wood floors?

A heating system from Radiant Design & Supply does not harm wood floors. Warm hardwood floors are delightful.

The moisture content of the floor is going to come to equilibrium with the moisture content of the air and has very little to do with the floor temperature.

Because the floor is the heating system, often there is no need for forced air heating and humidification. It is often forced air heating that dries the air, which dries wood. With radiant floor heating, the floor temperature is held at more constant temperatures (65-79 degrees) and not subject as much to extreme heating and cooling cycles.

We typically operate the floor heating using an outdoor reset control, which resets the fluid temperature based on outside air temperature. This provides just enough heat to carry the heating load without cycling the circulation off. The floor makes very small, even, and gradual changes in temperature as the weather changes. The outdoor reset control helps prevent the system temperature from becoming too high or too low and provides constant uniform space temperatures.

Why is carpet not recommended over radiant heated floors?

Your choice in flooring should be below an R1 value. Consider the R Value of all material over the hydronic heating installation. See the table below at the link and note that carpet plus padding exceeds the R1 value.

Comparative Flooring R Value PDF

What kind of tubing should I use with ThermoFin for my radiant system?

RADIANT recommends oxygen barrier PEX tubing. Any kind of standard nominally sized 1/2" or 3/8" oxygen barrier PEX will work. Copper tubing has also been used. Do not use potable water PEX. We supply ViegaPEX™ Barrier and ComfortPro PEX A with Barrier tubing. Contact us for prices.

How does ThermoFin address the issue of expansion noises in a radiant heating system?

ThermoFin has been designed to eliminate expansion noises. The PEX tubing snaps securely into the channel without any adhesives or fasteners.

Hydronic Radiant Floor Heating - ThermoFin U is a rigid, extruded aluminum plate designed to facilitate heat transfer in radiant floors. The heavy extrusion holds radiant (PEX) tubing securely in the patented snap channel, without additional fasteners or adhesives.

What are ThermoFin heat transfer plates? Why use them?

See our page "Why ThermoFin - Better by Design" for more details.

ThermoFins are extruded aluminum heat transfer plates designed and patented by Radiant Design & Supply, Inc, (formerly Radiant Engineering) made in the USA, for hydronic radiant heating. ThermoFin heat transfer plates are extruded of a high conductivity aluminum extrusion alloy.

ThermoFin plates transfer heat from the fluid flowing through tubing. The snap channel design of the rigid aluminum extrusion eliminates air spaces and maximizes the contact area available between the tubing and the heat transfer extrusion. It tightly grips the radiant tubing with sufficient force to minimize the thermal resistance at the critical tube/extrusion boundary. The heat is transferred to the floor, wall, or ceiling where the plates are installed.

ThermoFin was also designed to eliminate noises from expansion and contraction. PEX tubing has a relatively high rate of thermal expansion and is notorious for creating expansion noises in so called plateless "staple up" heating installations. The ThermoFin extrusion holds the tubing so tight, and the heat transfer from the tube into the extrusion works so well, that differential expansion between the tubing and the extrusion is eliminated along with the ticking and creaking noises associated with thermal expansion.

The ThermoFin system can perform as well or better than concrete radiant floor systems. ThermoFin out-performs other plate and board systems because of the thermal mass of extruded aluminum, the tight contact with the tubing, and direct contact with the surface where plates are installed.

How does ThermoFin improve radiant heating performance?

Using ThermoFin heat transfer plates lowers water temperatures required for effective radiant floor heating, increasing efficiency of boilers and other heating equipment. Outdoor reset controls are used to regulate a range of water temperatures with a ThermoFin system. The lower fluid temperatures also allow for use of low temperature heat sources such as condensing boilers and solar heating systems.

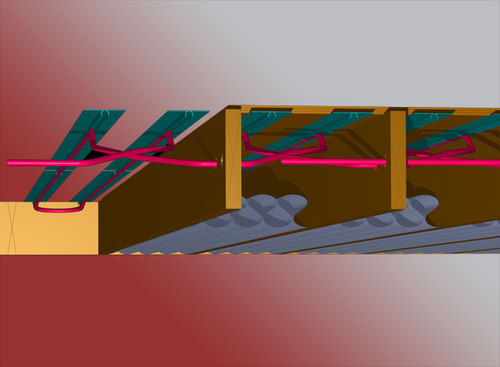

How are ThermoFin C and ThinFin C used?

ThermoFin C and ThinFin C are used between joists under existing floors. Self-drilling screws are used to attach the ThermoFin between the joists. The “C” shaped channel faces down. Tubing is snapped into the channel and tightly gripped without adhesives. The design of the “C” channel tightly grips 1/2” or 3/8” tubing and holds it securely. The tubing is installed in the "C" channel of the plate with a rubber mallet or pneumatic palm hammer. We rent a pneumatic palm hammer to our customers who purchase our heat transfer plates.

Our ThinFin C is a thinner gauge and narrower plate than ThermoFin C. The heavier gauge ThermoFin C is 1/2" wider than ThinFin C and has 18% more contact area. ThinFin C may be sufficient for buildings that are not in extremely cold climates or for well insulated buildings. Also, if the space between your joists are narrow so that you have to install the two rows of fins 6" on center instead of 8" on center, then you will have more plates spaced closer and could use the ThinFin. Two rows of plates are installed between the joists to pull loops of tubing in each joist. With less aluminum, ThinFin is more economically priced than ThermoFin.

To compare the heating from ThinFin C to ThermoFin C, you would run fluid 8 degrees hotter through ThinFin C to equal the heating from ThermoFin C.

Here is a helpful installation time saver shared from one of our customers who installed ThermoFin C without assistance. He writes, "To install the plates square to the joists and 8" OC, I made these wooden blocks. Turns out the width of a 2x4 is just about the right offset from the edge of the joist to the edge of the plate. The two strips of 1x3 are attached to a 6" length of 2x4, just a little bit below the edge. They provide a lip to support the plate. I just clip two of these blocks to the joist using vice-grip welding clamps, then I can slip the plate into the ridge and slide it back and forth to where I want it. Using this technique I can put the plates up very quickly without needing an assistant."

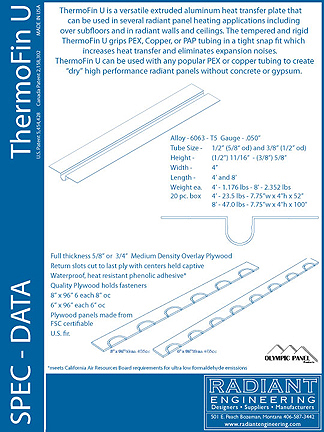

How is ThermoFin U used?

ThermoFin U heat transfer plates are installed under the finished flooring. Heated floors, walls, and ceilings can be created with ThermoFin U.

As with ThermoFin C, ThermoFin U grips the tubing with a tight fit that eliminates expansion noises and provides excellent heat transfer, unmatched by thin sheet metal plates, board products, or gypsum and cement pours. Plywood sleepers are placed over the fin between the channels to provide a solid nailing surface or surface for mortar and tile underlayment for installing the finished floor. A router is used to cut precision return bends from MDO plywood. The plywood resists job site abuse, presents a flat and dry surface for finish flooring, and holds nails, screws, and other fasteners securely. Wood diffuses heat at a rate that is about 3.25 times that of concrete. Aluminum diffuses heat at a rate that is 45 times faster than concrete. In floor heating, we prefer to bury the heat transfer plate below plywood sleepers to diffuse heat through the sleepers. This evens the temperature at the surface and carries the surface flooring at consistent, low temperatures that are just above the desired room air temperature. ThermoFin U can produce very high heating performance due to the proximity of the heating elements to the finish floor surface.

Is it a requirement that the sleepers in the “U facing up” installation method be milled to allow the flange to be recessed?

There are many good reasons for facing the channel down, including easier installation and better performance. A typical Thermofin U installation sequence starts with the return bends placed on top of the sub-floor with the tubing and then the placement of ThermoFin U. The sleeper material is cut and placed last. The plywood surface is very friendly for finish floor installations, especially hardwood.

There is no requirement to mill if the U channel faces up, but for some floor installations you will either want to fill it in, (thin-set with tile) or traverse it as with a backer board or plywood sub-layers.

We can produce recessed sleepers on a custom basis but we prefer to recommend installing the plates with the channel facing down and the sleepers placed on top. Installing the system this way, using our pre-cut plywood return bends, allows sleeper material to be cut on site with local plywood, dramatically lowering the cost compared with other panel products.

Heat transfer is enhanced with the channel facing down because both surfaces of the heavy plate are strongly sandwiched within the flooring system. As the whole flooring system must be brought to temperature to affect the surface temperature, the position of the plate within the floor system is less important. The floor heating system should be set up with water temperature control (outdoor reset), that allows the circulator to operate more continuously and allows changes to occur slowly. With this "keep up rather than catch up" control strategy, the floor heating system doesn't have to "accelerate" or cycle from cold to hot. Facing the ThermoFin U closer to the finish floor affects the acceleration time somewhat but doesn't buy the performance difference that you might expect. Practical details involving the flooring installation are more critical.

How does ThermoFin work under tile, wood, and carpet flooring?

ThermoFin can greatly increase the output of any radiant floor system. By increasing the amount of floor area that is actively engaged in heating, ThermoFin systems can produce more heat at lower water temperatures.

Ceramic and stone tile floors are the best heat conductors for flooring. Ceramic or stone tile, with an underlayment between the tile and ThermoFin U, is an excellent floor finishing choice for radiant heat.

Underlayment products, such as Schluter-DITRA, are installed with thin mortar that flows into cavities designed to grip and yet be flexible, so movement of the structure does not crack the tile flooring.

Wood floors also allow for good heat transfer. Wood flooring is not damaged by radiant heating when using ThermoFin appropriately. The moisture content of the floor is going to come to equilibrium with the moisture content of the air and has very little to do with the floor temperature. Because the floor is the heating system, often, there is no need for forced air heating and humidification. It is forced air heating that dries the air, which dries the flooring. With ThermoFin floor heating, the floor temperature is held at more constant temperatures, (65-79) and not subject so much to heating and cooling cycles.

Hardwoods like oak are about half to a third as conductive as masonry materials like concrete or even dense materials like granite. Softwoods are just a little less conductive than hardwoods. Aluminum is roughly 237 times more conductive than concrete.

The thermal "diffusivity" of a material is also an issue. This relates the mass of the material with its conductivity. In radiant floors, the mass of the material determines how fast the system can change in temperature. Wood diffuses heat at a rate that is about 3.25 times that of concrete. Aluminum diffuses heat at a rate that is 45 times faster than concrete.

Our heavy gauge extruded aluminum heat transfer plate, ThermoFin, pulls heat out of the tubing and increases the area for heat transfer. ThermoFin plate can be used in a variety of ways to conduct heat into and diffuse it through a wood flooring system at a very high rate, even compared with concrete systems. In our over-the-floor ThermoFin U system, we prefer to install the heat transfer plate below the plywood sleepers to diffuse heat through the sleepers. This evens the temperature at the surface and carries the surface flooring at consistent, low temperatures that are just above the desired room air temperature.

We typically operate the floor heating using outdoor reset control which resets the heating water temperature based on outside air temperature. This provides just enough heat to carry the heating load without cycling the circulation off. The floor makes very small, even and gradual changes in temperature as the weather changes. This helps prevent temperature overshoots and undershoots and provides constant uniform space temperatures.

Carpeted floors provide more thermal resistance, interfering with heat from the radiant floor. Heat transfer through higher resistance floors can be somewhat improved by increasing water temperature, but there are practical limits to the temperatures to which flooring materials should be subjected. ThermoFin can compensate for compromised radiant floors by providing sufficient heat at low, practical water temperatures.

Can radiant heating be added to an old house under original wood floors?

ThermoFin C aluminum heat transfer plates can be installed between the joists in the basement, below your old wood floor. It is very important to do a thorough heat load analysis of any structure to accurately determine the requirements for a heating system. RADIANT custom designs systems. The radiant floor system consists of the warm water source as well as the radiant floor. An advantage of hydronic heating is that a variety of heat sources are available and can be used where most appropriate. Gas fired boilers, electric boilers, and solar thermal systems are available. It is a closed system that is not connected with the potable water plumbing or the drain waste and vent piping in a house. Contact us to discuss the specific needs of your project, and whether ThermoFin C, ThinFin C, ThermoFin U, or a mix of these, should be used in retrofitting your old house.

Install the best R Value insulation batting under the ThermoFin C or ThinFin C and attach it to the joists without it touching the PEX or plates. Do not install a "radiant barrier" product. Invest in the best insulation instead.

What has to be done to add a radiant heating system with ThermoFin to an existing house?

The hydronic radiant floor is a closed system that uses water or a solution of water and propylene glycol as a heat transfer fluid – a means of moving heat from a central hydronic heat source, such as a boiler, into the flooring system where it radiates to rooms in the building. It has no connection with the potable water plumbing or the drain waste and vent piping in a house.

The radiant floor system consists of the warm water source as well as the radiant floor. An advantage of hydronic heating is that a variety of heat sources are available and can be used where most appropriate.

It is very important to do a thorough heat load analysis of any structure to accurately determine the requirements for a heating system. Radiant Design & Supply, Inc. custom designs systems. Contact us to discuss the specific needs of your home.

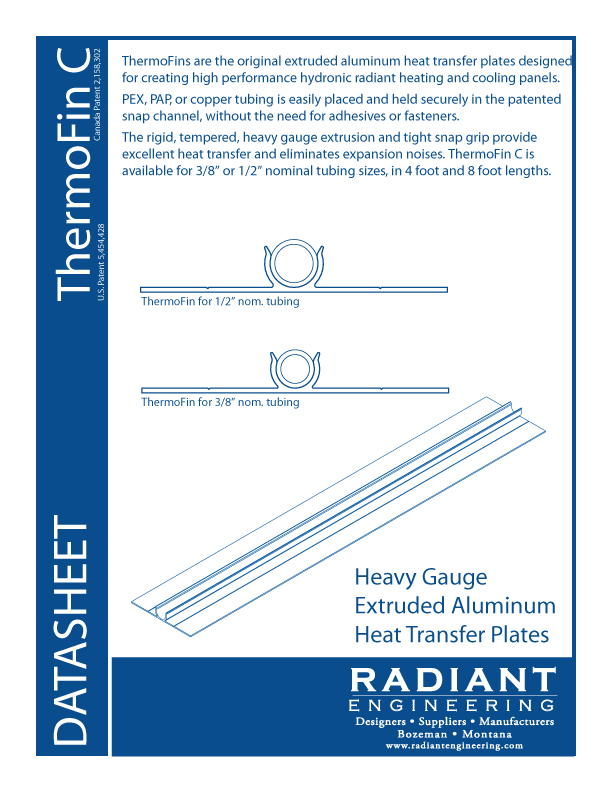

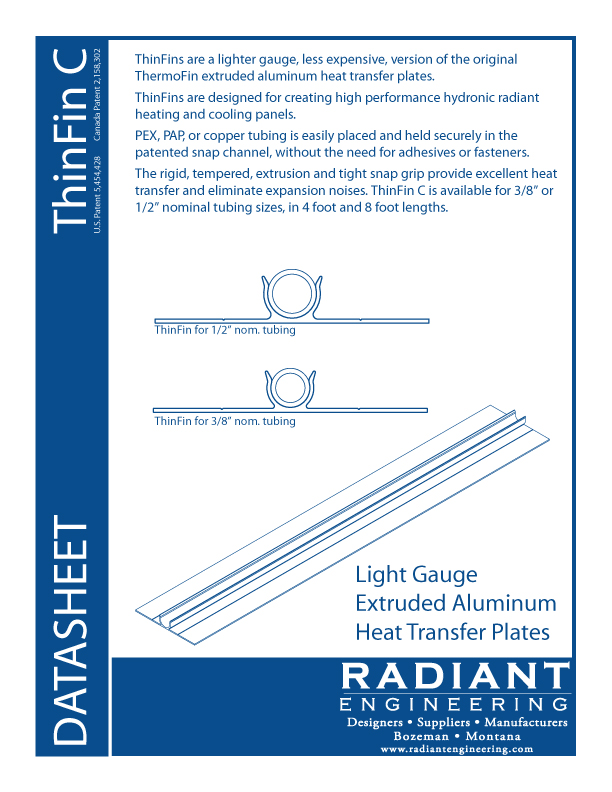

Do you have brochures for ThermoFin?

Click on the above images to open the PDF brochures.

In what sizes and lengths is ThermoFin available?

ThermoFin extrusions are available in 8 foot and 4 foot lengths.

You can cut them shorter with a carbide tipped blade for non-ferrous metal.

The channels fit 1/2” or 3/8” nominal sized PEX oxygen barrier tubing or copper tubing.

Extrusions are packaged 20 plates per box.

There is a handling charge for a box with fewer than 20 plates.

A thinner gauge of ThermoFin C is available, called ThinFin C.

1/2" nominal tubing ThermoFin C

3/8” nominal tubing ThermoFin C

4” wide

0.0625” thick

1/2" nominal tubing ThinFin C

3/8” nominal tubing ThinFin C

3.5” wide

0.050” thick

1/2” nominal tubing ThermoFin U

3/8” nominal tubing ThermoFin U

4” wide

0.050” thick

Are radiant heating systems with ThermoFin energy efficient?

It is important to understand that heat transfer has not "increased" so much as resistance to heat transfer has been reduced. Radiant heating with ThermoFIn allows operation with low fluid temperatures that boost efficiency in a variety of ways. It decreases undirected heat losses from boilers, piping circuits, and other system components. Lower fluid temperatures allow boilers to pull more heat from exhaust gases, and less heat is lost up the flue. Low operating temperatures are needed to get the best operation of modern, high efficiency condensing boilers, heat pumps, and solar energy systems. Systems that operate at lower temperatures can take advantage of new, sophisticated heating controls that increase comfort and efficiency by carefully regulating system temperatures. See also the infrared product comparison on our website at The Heat Exchanger Blog.

Is radiant heating comfortable?

Radiant floor heating systems are well known for being extremely comfortable. A heating system that operates by producing uniform temperature room surfaces allows occupants to come to thermal equilibrium with their surroundings. ThermoFin creates a more uniform radiant panel surface temperature, which lowers the system temperature required for effective heating. As panel surface temperatures approach desirable room air temperatures, comfort is increased. Many homeowners choose radiant heating instead of forced air heating because they prefer the clean, quiet, even heating that does not blow dust or allergens into the air.

Will ThermoFin radiant heating save on heating bills?

High efficiency heating systems decrease fuel use and heating costs, reduce system wear, and increase reliability. Maintenance costs and nuisance call-backs are reduced. Comfort and heating effectiveness are enhanced, providing a return on investment. ThermoFin increases efficiency, comfort, and effectiveness of your radiant heating system.

Why doesn't Radiant Design & Supply sell ground source heat pumps?

Our point of view is that ground source heat pumps are too costly and their energy efficiency has been highly exaggerated. This article at GreenBuildingAdvisor.com reviews the issues of ground source heat pumps and why we do not recommend them.

Is there a difference between PEX manufacturers? There are many different ones out there – does one perform any better than the other? Which do you recommend considering quality and price?

No, there really aren't huge differences between one brand of PEX and another. You do want to pay attention to the fitting system that you use, however. We sell Viega PEX. This US made product has a PE layer on top of the EVOH oxygen barrier. This PE layer protects the EVOH and helps keep it from squeaking.

What kind of technical support can I expect from Radiant Engineering?

Founded in 1979, Radiant Design & Supply, formerly called Radiant Engineering, specializes in providing the means and materials to produce first quality, energy efficient, hydronic heating systems. RADIANT employs technical specialists with practical fabrication and installation experience. Professional design expertise is combined with world class equipment to create successful projects for architects, contractors, do-it-your-selfers and homeowners.

RADIANT is experienced in the design and installation of hydronic heating systems that use a variety of fuel types including natural and propane gas, electricity, wood fuel, and solar energy systems. These systems may employ a variety of hot water driven devices or sub-systems that distribute heat from the central source. These include radiant floors, hot water radiators and baseboards, indirectly fired domestic water heaters, and snow melting systems.

RADIANT makes available design services that can be very useful to anyone planning the installation of hydronic heating systems, especially radiant floor heating systems. RADIANT provides competent heat loss evaluation, heat source and heating distribution equipment selection and sizing, CAD based radiant floor layout designs, equipment and installation specifications, and detailed mechanical and control schematic drawings.

RADIANT also provides custom mechanical system fabrication services. Pre-fabricated system kits and packaged designs facilitate successful on-site installation. Kits are pre-plumbed, pre-wired, tested and custom-built to Radiant Design & Supply’s designs and specifications.

RADIANT provides world class hydronic heating equipment including Viessmann and Crown boilers, PEX radiant tubing & fittings, tubing manifolds, zone valves, circulators, thermostats and electronic controls, hot water baseboards, panel radiators, indirect water heaters, solar energy systems, and more. See our products pages for more information on the equipment.

If you have more questions, contact us directly by phone or email from our contact page.